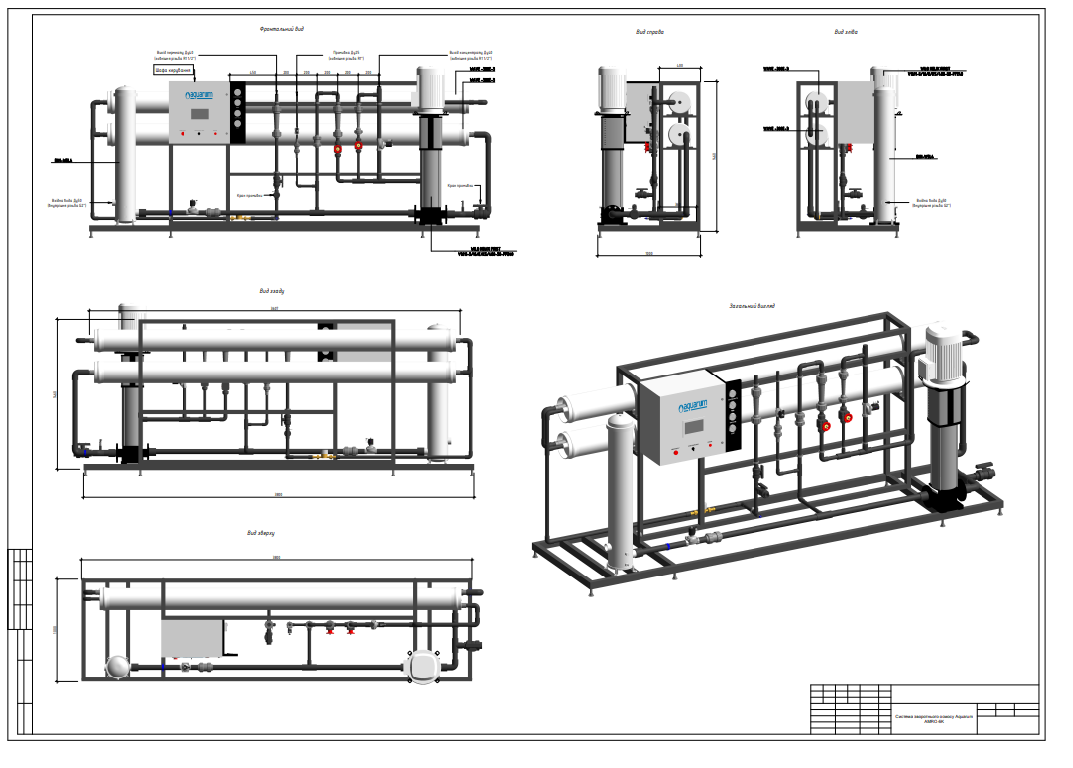

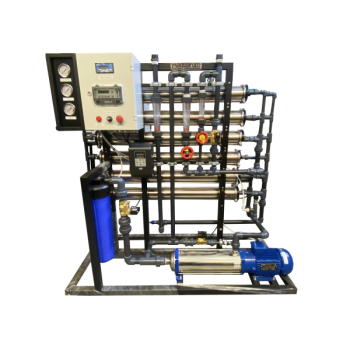

The AMRO-4K reverse osmosis system is a technological unit designed to purify water from soluble salts (demineralization or desalination) by reverse osmosis using special semi-permeable membranes. Semi-permeable membranes are enclosed in special housings made of metal or fiberglass. The membrane in the housing is a membrane module – the main element in which the reverse osmosis process takes place. Other elements of the system are necessary for the normal functioning of the membrane module: maintaining the required pressure, regulating flows, ensuring the required start and stop process of the plant and the functioning of technological protections.

Structurally, the unit is mounted on a steel frame and has a stainless front panel with monitoring and control devices. All pipelines are made of food-grade polyvinyl chloride.

Main components of the plant:

– Cartridge type pre-filter. It is necessary to protect the pump, membrane module and shut-off and control valves from mechanical contaminants larger than 5 microns.

– Multistage high-pressure centrifugal pump. It is necessary to create the required pressure in the membrane module, which provides the reverse osmosis process.

– A set of shut-off and control valves. Necessary for the implementation:

– production mode

– hydraulic flushing mode

– parking flushing mode

– concentrate flow control

– recycle flow rate control

– connection of a chemical washing station.

– Automation system. It is necessary for:

– proper functioning of the plant operating modes.

– automatic pressure control in the module.

– protection of the pump against dry running.

– protection against high and low pressure in the module.

– protection against high pressure in the permeate line.

The automation system has an output for connecting a preliminary (booster) pump, an antiscalant dosing pump and an external alarm.