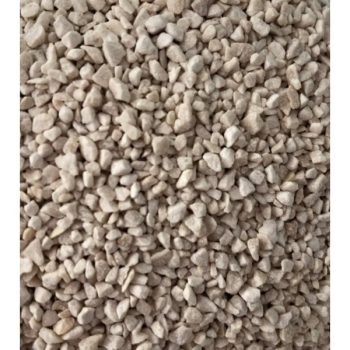

Filter AG is a filter media made of clinoptilolite ore (a product of volcanogenic-sedimentary origin) used for water clarification.

Filter-Ag has a number of advantages over most granular filter media used for mechanical treatment of water from suspended solids. The broken edges and irregularities of the particles in this material provide a large surface area and a complex path of water flow through the loading layer, due to which the level of mechanical treatment up to 20-40 microns is achieved.

Due to the larger size of the particles compared to other filtering materials, pressure losses in the filter are reduced and deeper penetration of contaminant particles in the loading layer occurs, thereby extending the service life of the material. Also, the large size of Filter-Ag particles and their irregular shape prevent the filtered contaminants from sticking to the upper loading layer and its subsequent blocking, as it happens in standard sand filters. Due to the light weight of the material, water consumption is reduced and greater layer expansion is achieved to remove mechanically filtered particles during backwashing. This ideal combination of particle shape, size and density makes Filter-Ag a highly effective filter media.

Although Filter-Ag is not designed to remove iron from water, practical experience has shown that the uneven surface of its particles retains iron flakes quite well after oxidation of its soluble form.

The use of Filter-Ag in mechanical filters can significantly reduce capital and operating costs of water purification from suspended solids due to low pressure losses, high productivity in operating mode, as well as low water consumption for backwashing.

The Clack Filter-Ag can be used for both pressurized and gravity water streams. Because of its density, Filter-Ag is also successfully used in multimedia filters.

Properties:

Color: Light gray to near white

Bulk density: 0.38-0.42 kg/dm3

US Mesh particle size: 12 × 30

Effective size: 0.67 mm

Density: 2.25 g/cm3

Coefficient of homogeneity: 1.8

Mohs hardness: 6.0

Filter AG application conditions:

Filter bed height – 60-90 cm (24-36 inches)

Layer expansion during wash down – 30-40%

Speed of water flow in operating mode – 30-50 m3/h and higher

Speed of water flow in backwashing mode – 30-50 m3/h

Maximum water temperature – 60°C

Working parameters:

pH wide range

Treated water temperature max: 60°C

Feed layer height: 600…900 mm

Minimum free space in the filter: 50% of the layer height

Linear filtering speed in operating mode: 12 m/h (although higher speeds are often used)

Linear opening velocity: 20-24 m/hour

Layer expansion during backwashing: 20…40% of the loading layer height

Keep the load in water for 12 hours before first ripping.

Advantages of using the Filter AG :

Effective removal of suspended particles of rust, silt and organics larger than 5 microns from water

Large filtering area of the material (1000 times larger than that of quartz sand)

Long filter cycle

Light weight of the material reduces the water consumption for backwashing

Filter AG Plus has a lower pressure drop per bed than other filter media

Packaging: polyethylene bags 28.3 l