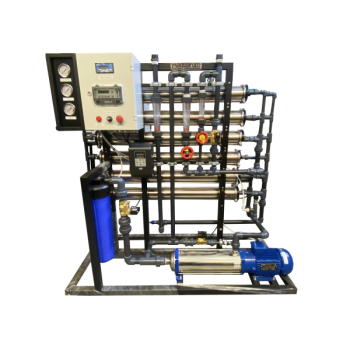

The Aquarum ROECO-250 reverse osmosis unit by TM Aquarum is highly efficient equipment for demineralization and removal of mechanical impurities and organic compounds from water. This unit has a capacity of up to 250 l/hour and a long service life.

Hyadranautics ESPA4-LD-4040 membrane included.

Reverse osmosis systems by this company are in great demand in the water purification equipment market due to their affordable cost, high build quality and, as a result, long service life. This unit is a functionally complete module, all system equipment, control and shut-off valves are mounted on a metal frame, which allows you to significantly save useful space in the room.

Aquarum units are developed using innovative approaches and professional programs, which guarantees full automation of the water purification process with the ability to track and monitor the main parameters of the system. Ease and reliability of control is ensured by a microprocessor controller.

What are the principles of osmosis and reverse osmosis, and what is their fundamental difference?

“Osmosis” is the ability of water to pass through a semipermeable membrane that separates solutions with different salt concentrations. Direct osmosis occurs due to the fact that water with a low salt concentration diffuses through the membrane due to osmotic pressure until a balance is reached between the aforementioned pressure and the pressure of the liquid column with a high salt concentration. Reverse osmosis is the same process, but in the opposite direction: pressure applied from the side of the concentrated solution (that is, the water requiring purification) causes pure water to diffuse from it to the other side of the membrane. The membrane is designed in such a way that only pure water can pass through it, without any impurities or contaminants, so at the outlet the consumer receives a purified product suitable for consumption.

Thus, the following process occurs with the help of this unit:

the initial water is fed under pressure to the osmosis and purified on the prefilter from large contaminants;

using a pump, the pre-purified water is fed to the reverse osmosis membranes. The design of the membranes allows only purified and desalinated water (permeate) to pass through, thus all residual contaminants, salts, etc. do not pass further than the membranes and are washed off their surface with water into the sewer (concentrate). The volume of the concentrate is about 25% of the water supplied for purification;

the remaining water (purified, about 75%) is sent to the storage tank, from which it is taken apart for consumption.

The basic configuration of the unit is as follows:

stainless steel frame;

high-pressure pump;

membrane holders made of stainless steel AISI304;

fine prefilter with a 5 μm filter element;

PPR piping (FV-plast, Czech Republic);

electric control cabinet with an industrial controller and manual control mode;

A set of instrumentation and automation equipment: rotameters (permeate, discharge), solenoid valves (inlet, flush, permeate flush), regulating valves (drain and recycle), vibration-resistant pressure gauges, sensors (dry running, permeate pressure, float for tank).

In addition, the following options can be added:

reagent dosing station;

unit for mixing feed water into permeate through an ultrafiltration membrane;

chemical membrane flush unit;

1 μm filter element;

permeate production meter (counter);

conductivity sensor.

We always meet all customer requests, so we allow for special delivery conditions: with pumps from other manufacturers, delivery with membrane elements, special design of the unit, delivery and installation.